Description

PR4P Self Feeding Drilling

PURROS® Self Feeding Drilling Unit Parameters

Mode: PR4P

No-load speed: 210-6100R/M

Drilling diameter: Aluminum: 5-19mm / Cast iron: 1.5-15.5mm / Steel: 1.5-13mm

Spindle stroke: 100mm/150mm

Cutting feed stroke: 40mm, 60mm, 80mm, 100mm, 130mm

Motor power: 0.75/1.1kw

Feed driving: 1800N

Air consumption: 6-10L

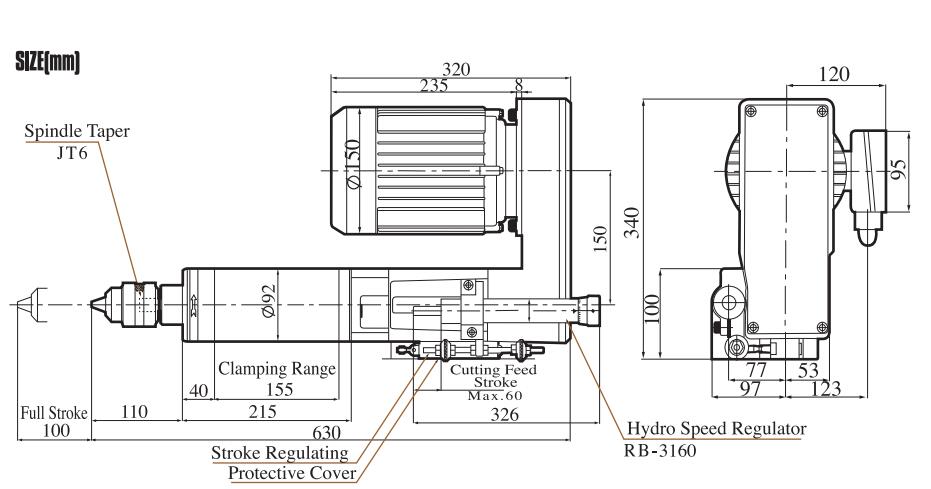

PURROS® Self Feeding Drilling Unit Size

PURROS® Self Feeding Drilling Unit Characteristics

| Model number |

No-Load rotational speed | Chucking Capacity | Drilling capacity | Stroke | Motor Specifications |

Thrust | Weight | |||||

| 50 Hz | 60 Hz | Aluminum (ADC) |

Castiron (FC200) |

Steel (S45C) |

Total stroke |

Cutting feed stroke output |

Output | Pole number |

||||

| min-1 | mm | mm | mm | mm | kw | P | N | kg | ||||

| PR4P-6061 | 6100 | 7300 | 6.5 | 5 | 1.5 | 1.5 | 100 | 0-40 | 0.75 | 2 | 1800 | 31 |

| PR4P-6061L | 150 | 36 | ||||||||||

| PR4P-6045 | 4500 | 5400 | 5.5 | 2 | 2 | 100 | 31 | |||||

| PR4P-6045L | 150 | 36 | ||||||||||

| PR4P-1330 | 3000 | 3600 | 13 | 7 | 3.5 | 3 | 100 | 31 | ||||

| PR4P-1330L | 150 | 36 | ||||||||||

| PR4P-1320 | 2000 | 2400 | 9 | 5 | 4.5 | 100 | 31 | |||||

| PR4P-1320L | 150 | 36 | ||||||||||

| PR4P-1314 | 1480 | 1700 | 10 | 6 | 6 | 100 | 31 | |||||

| PR4P-1314L | 150 | 36 | ||||||||||

| PR4P-1311 | 1100 | 1400 | 11.5 | 8.5 | 7.5 | 100 | 1.1 | 4 | 31 | |||

| PR4P-1311L | 150 | 36 | ||||||||||

| PR4P-1308 | 850 | 1000 | 12.5 | 10.5 | 8.5 | 100 | 31 | |||||

| PR4P-1308L | 150 | 36 | ||||||||||

| PR4P-1306 | 600 | 700 | 14.5 | 12 | 9.5 | 100 | 31 | |||||

| PR4P-1306L | 150 | 36 | ||||||||||

| PR4P-1304 | 540 | 550 | 16.5 | 13.5 | 11.5 | 100 | 35 | |||||

| PR4P-1304L | 150 | 40 | ||||||||||

| PR4P-1303 | 400 | 380 | 18 | 14.5 | 12 | 100 | 35 | |||||

| PR4P-1303L | 150 | 40 | ||||||||||

| PR4P-1302 | 330 | 250 | 19 | 15.5 | 13 | 100 | 35 | |||||

| PR4P-1302L | 150 | 40 | ||||||||||

1. High-precision

Core technology of Electro Pneumatic Drilling Units is played very well, which completely strengthened the versatility of the product and thus made the high precision of Drilling Units reflected extremely.

2. High rigidity

Axial rail structure is used, which greatly improved the overall rigidity and fully guaranteed the stability of the hole machining.

3. High performance

A unique dual sealing structure and round body that is easy and convenient to be installed are available at the end of spindle, which can meet variety of holes machining requirement.

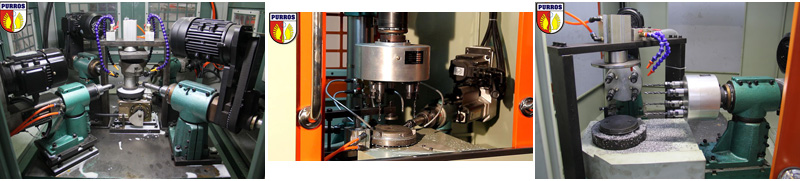

Products can be equipped with Self Feeding Drilling Unit

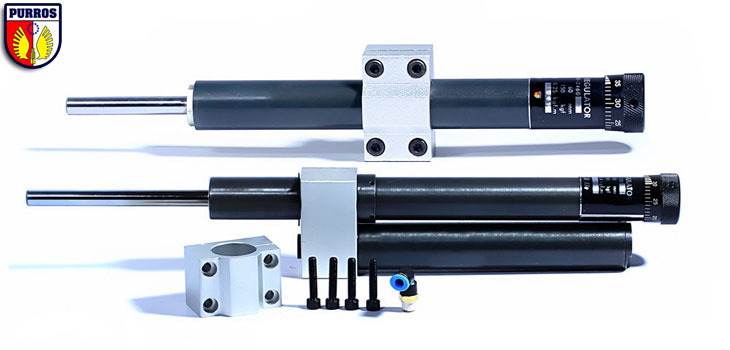

1. Hydraulic Damper (PURROS® Hydro Speed Regulator)

Speed can be adjusted arbitrarily from lower to higher by a hydraulic feeding speed control device.

PR4P Self Feeding Drilling

2. Multi-axis machining head (PURROS® Multiple Spindle Heads)

Multi-axis machining head can be amounted, which can achieve high efficiency drilling and meet different requirements of machining axes and axis spacing. Extensive multi-axis machining head sizes are available in PURROS®.

PR4P Self Feeding Drilling

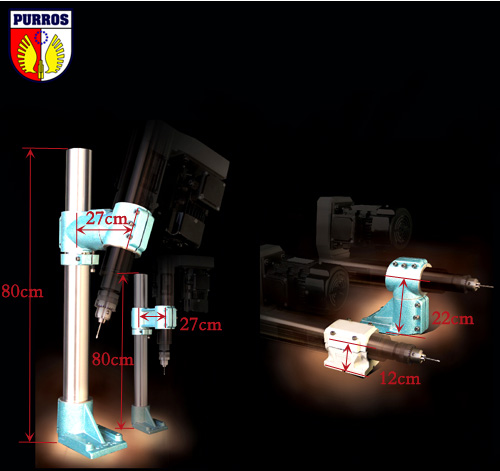

3. Desktop support (PURROS® Universal Stand)

Such desktop support is suitable for any machining directions, which can fix the Drilling Units angle freely.

PR4P Self Feeding Drilling

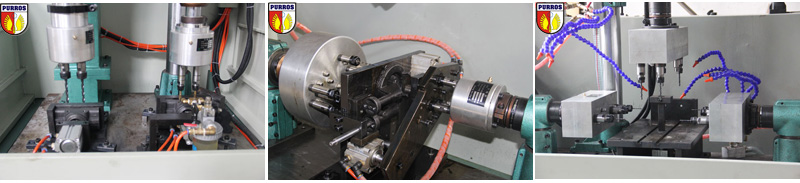

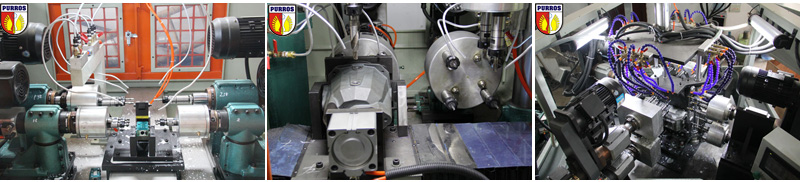

PURROS® Special Purpose Machine

Multiple Drilling or Tapping Machine

Multi Station Drilling or Tapping Machine

Rotary Index Drives Special Purpose Machine

Sliding Table Special Purpose Machine

Rotary Table Special Purpose Machine